Engineering

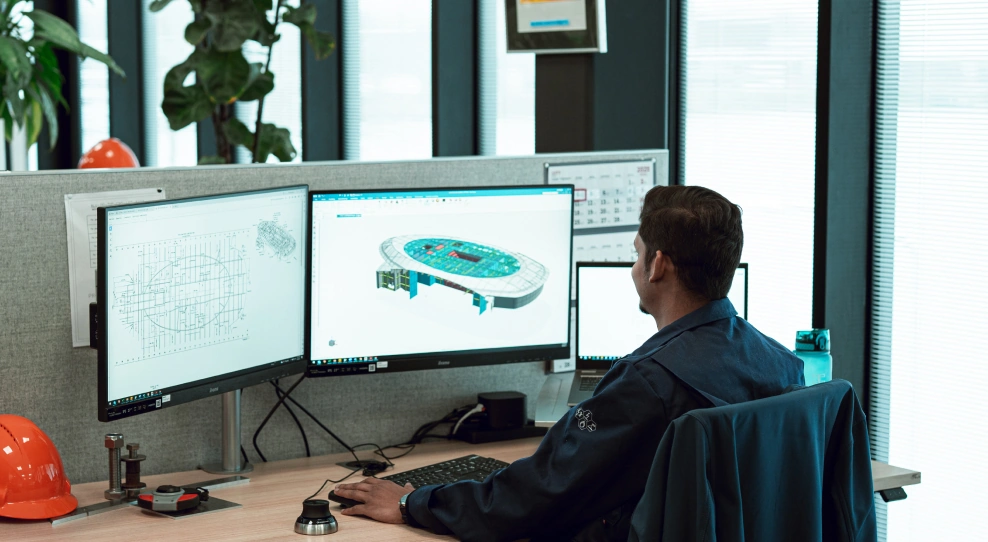

The engineers of Shipyard Slob contribute to the development of the ship design and then take care of the detail engineering or working drawings of the hull using 3D software.

Our engineering team is a nice mix of very experienced former production employees, who know how to build a hull and young and driven engineers, who are very skilled with our PLM system (Teamcenter) and our 3D software (Cadmatic/NUPAS, Siemens NX, Rhino and others). The engineering of Shipyard Slob works on its own projects, but also does work for shipbuilders and engineering parties inside and outside Feadship. When additional engineering capacity is needed, Shipyard Slob can rely on a number of cooperating engineering parties.